DEM Solutions, which is involved in engineering applications for discrete element method (DEM) simulation, has released EDEM 2.5 software with increased scalability and performance to simulate complex bulk particle processes required by the global equipment manufacturing and process industries.

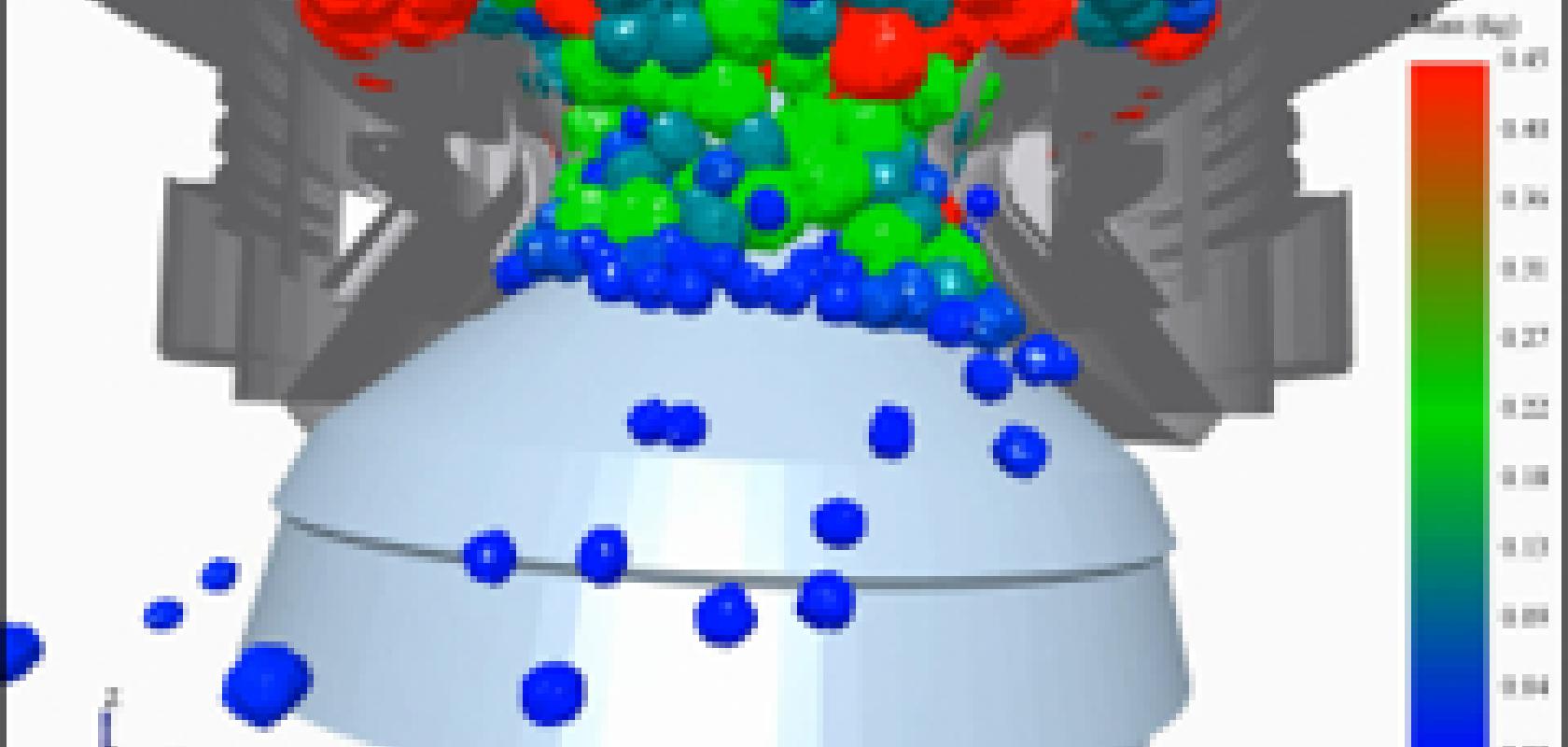

The EDEM solver is highly parallelised for operation on multi-core shared memory parallel computers, delivering what it says is the fastest and most scalable DEM simulation on the market. EDEM 2.5 further expands the functionality of the EDEM API to model particle processes such as drying, sorption, coating and comminution involved in manufacturing processes in industries including minerals processing, metals manufacturing, pharmaceuticals, consumer packaged goods and food processing.

'EDEM provides an easy-to-use yet highly extensible platform for modelling a wide range of particle-scale physics and multi-physics through co-simulation with CFD and EMAG solvers,' said John Favier, CEO of DEM Solutions.

'EDEM 2.5’s new API capabilities provide engineers an enhanced set of capabilities for simulation of particle processes such as particle breakage in crushing and milling of ore in comminution circuits, coating of tablets, pellets and food products, and removal or take-up of liquids and gases by particles.

'It expands on the existing capability to customise the properties of each particle, contacts with other particles and interaction with equipment and surrounding fluid or EMAG fields by enabling the size and shape of particles to change, as well as dynamic creation and disappearance of particles in response to the physical process conditions.'