Computer modelling has been used to improve stainless steel tubing that was too hard and brittle to meet the requirements of nuclear weaponry.

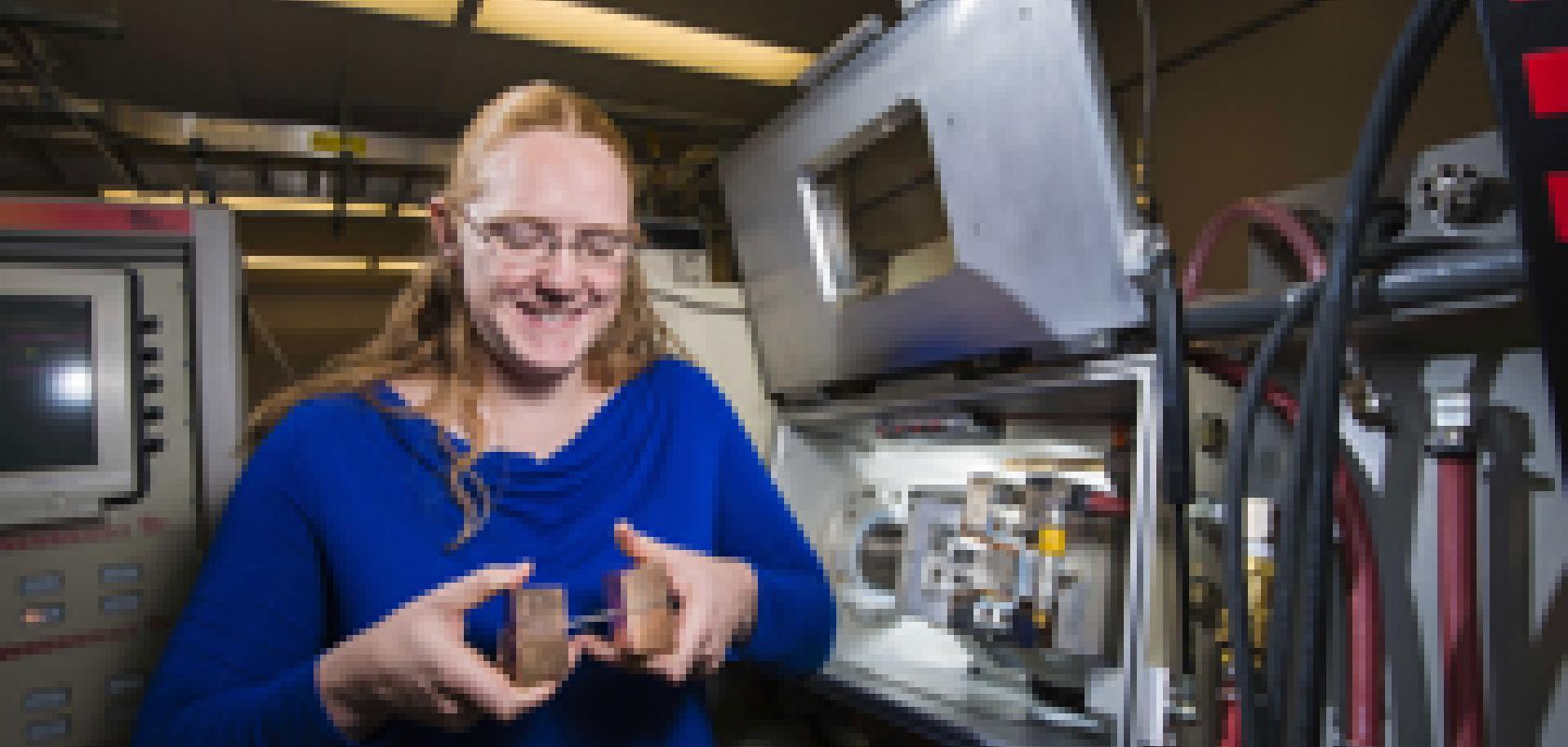

Sandia National Laboratories researchers Lisa Deibler and Arthur Brown partnered with the National Nuclear Security Administration’s Kansas City Plant to work on the issue.

Sandia’s modelling, coupled with experiments, allowed the rapid design of an annealing process to soften the tubing while keeping the metal’s desired structure. The model predicted how the microstructure would be affected by variations in the process, which improved researchers’ confidence that the heat treatment would produce parts that met specifications.

Brown, a modeller at Sandia’s site at Livermore, California, said working on the model was a natural extension of a larger project, supported by Sandia’s Nuclear Weapons programme, called Predicting Performance Margins. Under that programme, numerous Sandia researchers are studying the way microstructure affects properties of materials at various scales.

Brown became involved in the project as a member of a team that developed a thermal-mechanical modelling tool to predict how microstructure and other properties change during forging. That led to his collaboration with Deibler and Joe Puskar, her Sandia technical adviser, on thermal profiles for welds.