Tohoku University Graduate School of Engineering, Graduate School of Information Sciences, and NEC Corporation have announced a collaboration aimed at developing composite materials for aircraft. The research and development will be carried out using NEC's vector supercomputer SX-Aurora TSUBASA to accelerate the development of carbon fibre reinforced plastics (CFRP) for aircraft.

This research is being conducted under the Cross-ministerial Strategic Innovation Promotion Program, a national project led by the Japanese government, aiming to reduce the development costs, manufacturing costs, and development period of composite materials for next-generation aircraft by up to 50 per cent when compared with conventional methods.

In the field of composite materials for aircraft, Japan has produced a wide range of materials but this requires a great deal of time and expense. Digitalisation is helping to advance this process, enabling shorter delivery times of products to market.

In order to efficiently develop high-performance composite materials in a short period of time, strategic research and development that combines a variety of academic knowledge, such as materials science and information sciences, is required, rather than just traditional methods that depend on conventional experiments and expertise.

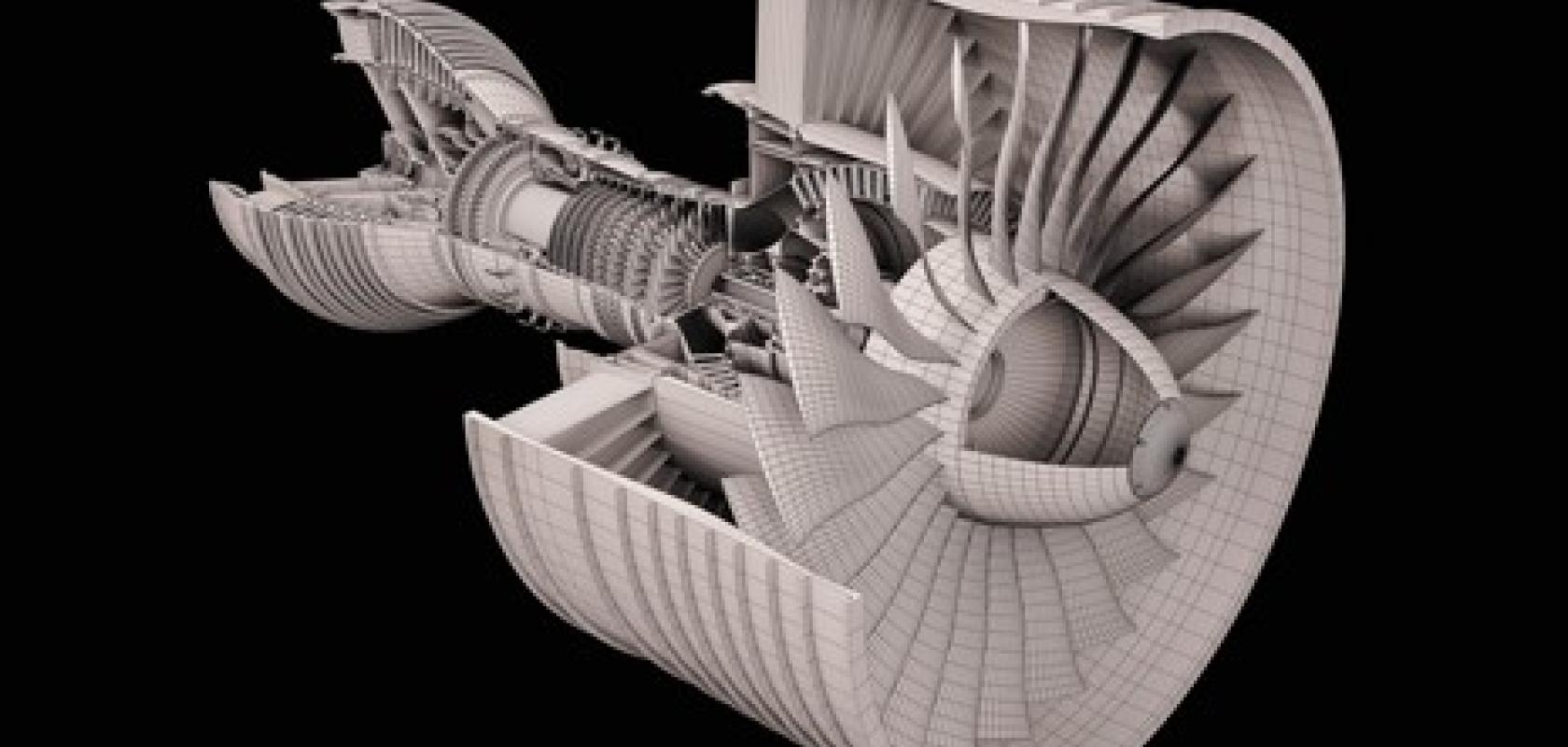

The aim of this research is to create an integrated system capable of digitally developing CFRP for aircraft structures using simulation tools developed by Tohoku University and NEC's SX-Aurora TSUBASA vector supercomputer.

Specifically, by implementing simulation codes on a supercomputer that analyzes mechanical responses ranging from as small as the molecular level to the aircraft wing and fuselage, the processes of material selection, design, and others can be performed at high speed and at multiple scales. By utilising this system as an integrated simulation platform, tailor-made material development becomes possible to more effectively meet the demands of aircraft manufacturers.

Research projects

Development of a multiscale simulation platform (Professor Tomonaga Okabe, Graduate School of Engineering, Tohoku University)

Utilising outputs from scientific research in composite materials, Tohoku University has developed a variety of simulation tools for CFRP, together with companies participating in Japan's Cross-ministerial Strategic Innovation Promotion Program. The integrated systems developed in this R&D will be applied to a wide range of future vehicles, in addition to aircraft.

Application of high performance computing technology (Professor Hiroaki Kobayashi, Graduate School of Information Sciences, Tohoku University)

Simulation programs for materials integration systems will be vectorised and parallelised for the SX-Aurora TSUBASA vector supercomputer in order to significantly reduce the execution times of the simulation programs. This research emphasizes cooperation with participating companies in order to accelerate programs.

System construction using supercomputer (NEC)

The SX-Aurora TSUBASA supercomputer consists of vector engines that perform high-performance simulation programs and a vector host that performs a wide variety of processes. This R&D utilises NEC's supercomputer technologies and system construction know-how to systematise simulation programs with the SX-Aurora TSUBASA supercomputer. The materials integration system will combine both data science and optimal material design.