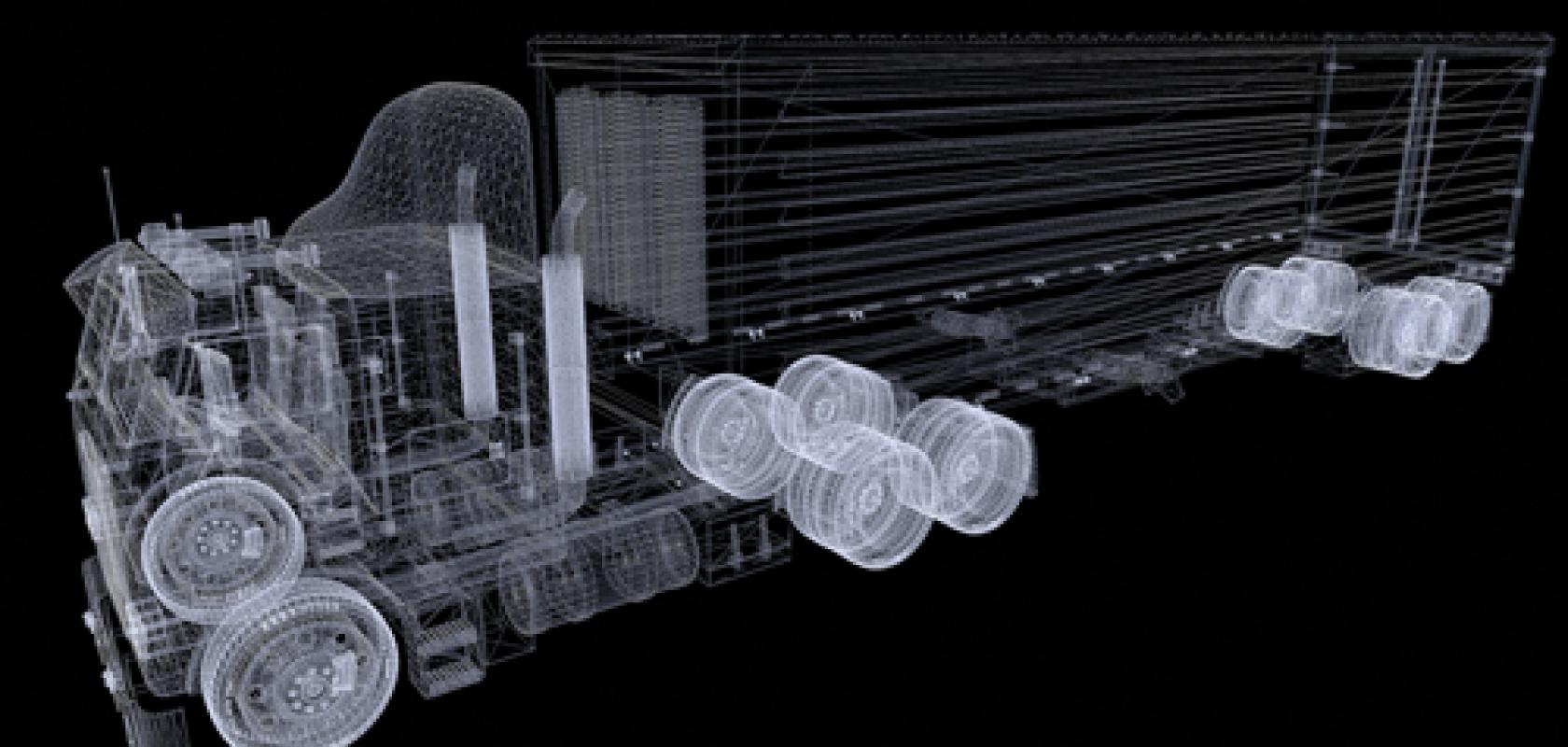

The design and development of industrial vehicles is a hugely competitive business that requires companies employ simulation to compete across all areas of vehicle development – from traditional disciplines such as CFD to more recent additions such as acoustic, heat transfer and fuel cell/battery simulation.

By employing varied methods for modelling and simulation, and even coupling multiple parameters within a single optimisation or redesign project, a company can make significant savings on costs, development time or increase the performance of a component. Bjorn Sjodin, vice president of product management at COMSOL, explains that the latest industrial vehicles – as with other areas of automotive design – often involve high-tech components, composite components to assisted driving, or vehicle automation systems which require significantly more complex simulation.

‘Today’s vehicles are immensely high-tech products, and there is a need for simulations in many different areas.’

Sjodin said this approach of using virtual development not only saves time but also allows users to adapt designs more easily, as there is no requirement for physical prototyping until later in the design project.

Simulation on an industrial scale

The most important reason for simulation ‘may be to reduce the number of physical prototypes that need to be built and instead build such prototypes in a simulation environment,’ stated Sjodin. ‘Design mistakes can be corrected very early on in the design process, and thousands of design ideas can be tested virtually before the first physical prototype is built.’

Design ideas can be tested virtually before the first physical prototype is built

COMSOL has worked on many projects to accelerate development projects for industrial vehicles, from strengthening existing structures to exploring wireless charging technologies. In each case, simulation is enabling smarter or more efficient designs within fewer development cycles.

Sjodin gave one example where integrated steel and mining company ArcelorMittal used COMSOL Multiphysics heat transfer and multiphase flow capabilities to optimise the design of laser-welded blanks (LWBs). An LWB is a metal sheet of varying thicknesses and grades used to minimise and control the amount of material employed in vehicle manufacturing. In this scenario, the team wanted to reduce the material used but still meet particular safety regulation standards.

‘Automotive design tasks frequently deal with contradictory requirements of this kind: make something stronger while making it lighter,’ explained Sjodin. ‘Simulations here can be invaluable since modern tools can be set up to sweep over a large range of cases, or automatically optimise for a certain objective.

Another example comes from a project involving WiTricity, a company founded in 2007 to commercialise a new technology for wireless electricity invented and patented two years earlier by a team of physicists from the Massachusetts Institute of Technology (MIT), led by Professor Marin Soljačić.

For this project, WiTricity optimised technology for wireless charging of electric vehicles. In this case ‘electromagnetic simulations help with the intricate design of resonant coils responsible for transferring the energy. This technology has the potential of eliminating the hassle of cables in future vehicles,’ commented Sjodin.

COMSOL is constantly working on improving the software from a variety of perspectives

Solving modern simulation challenges

In addition to improving on existing designs in this increasingly complex and competitive environment, simulation can also help users to overcome significant challenges as they are presented. Sjodin explained that the multi-faceted nature of many projects pulls designs in competing directions, which in itself can be a significant challenge.

‘The use of multiphysics software, such as COMSOL Multiphysics, allow engineers to consider all of these requirements in one go and increase the probability of meeting deadlines with a successful design,’ he said.

The desire to help COMSOL users meet the challenges that arise in their projects are leading the company to develop new software features, including some features introduced due to requests from the user community.

Sjodin explained that COMSOL is ‘constantly working on improving the software from a variety of perspectives: performance improvements, efficient use of the latest CPUs, cluster, and cloud technologies and usability’.

‘Something we are continuously working on by leveraging the latest in hardware and algorithmic advances,’ said Sjodin. ‘One example would be recent requests for simulation technology for testing batteries and fuel cells, using a technique known as AC impedance spectroscopy.

‘COMSOL implemented such simulation tools recently to meet requests from engineers working with batteries and fuel cells,’ concluded Sjodin.